Membrane keypads are a frequently preferred control interface in electronic devices due to their thin and flexible structure. Unlike mechanical keypads, they use a structure consisting of thin layers that are sensitive to pressure instead of a physical key mechanism. While the upper surface is usually made of durable materials such as polyester or polycarbonate, there is a conductive circuit layer underneath. When the user presses a key, the circuit is closed and the signal is transmitted, thus performing the command. Their high resistance to water, dust and chemicals makes membrane keypads an ideal choice in many sectors such as industrial automation, medical devices, defense industry and consumer electronics. At the same time, being lightweight, ergonomic and energy-efficient offers significant advantages over mechanical alternatives. Today, membrane keypads, produced with customizable designs and advanced printing techniques, adapt to different requirements in terms of functionality and aesthetics and expand their areas of use every day. Especially thanks to its durability and maintenance-free structure, it offers a long-lasting and cost-effective solution.

How Does a Membrane Keypad Work?

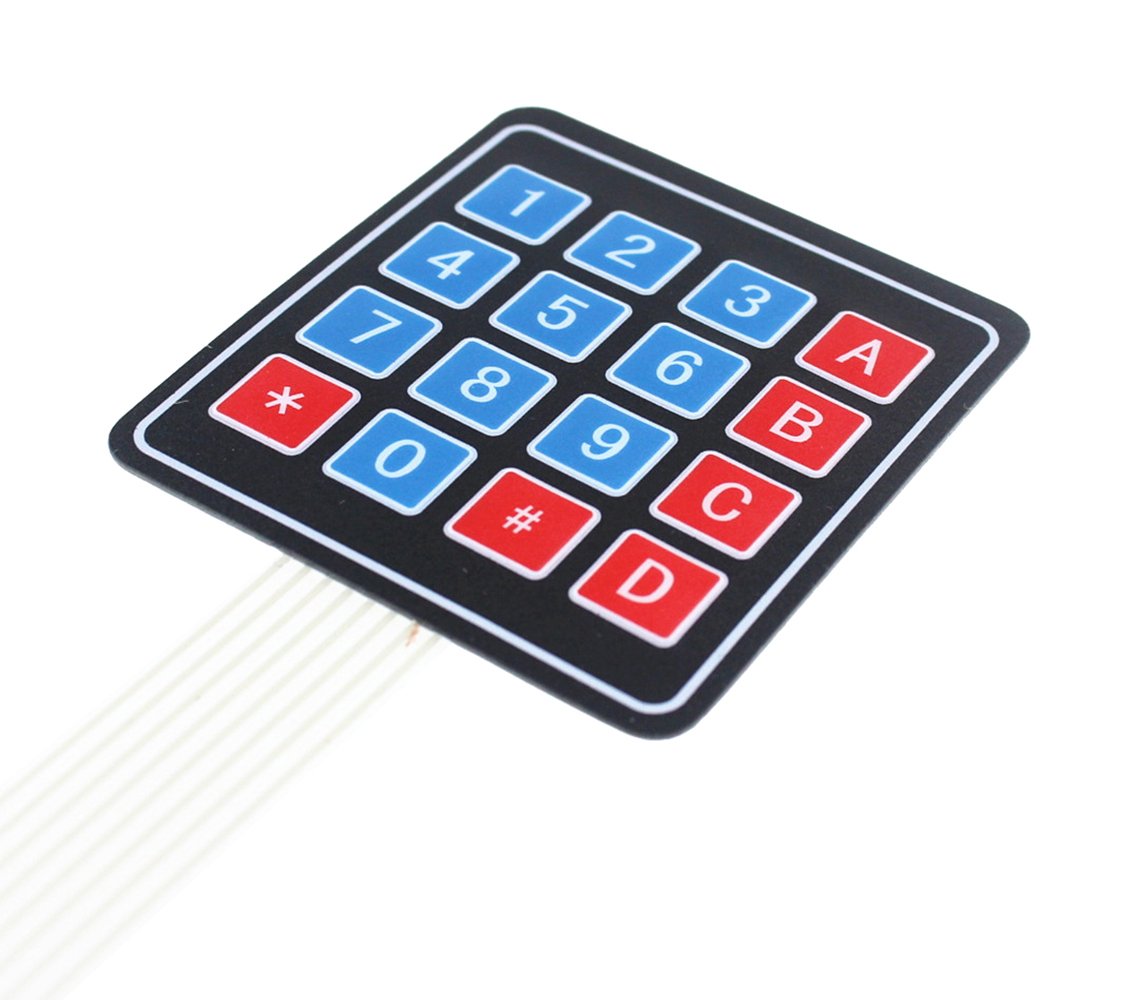

Membrane keypads have a pressure-sensitive multi-layer structure and operate using flexible circuits instead of mechanical keys. The upper layer usually contains graphically printed polyester or polycarbonate materials. There is a conductive circuit layer underneath. When the user presses a key, the upper layer stretches downward and creates an electrical signal by contacting the conductive circuit. This signal is detected by the device it is connected to and enables the relevant command to work. Since this system does not have mechanical components, it offers silent, lightweight and energy-efficient use.

Tuşhan Elektronik provides optimum performance by using precise circuit designs and high-quality materials in membrane keypad production. Manufactured to be resistant to water, dust and chemicals, these keypads offer a reliable solution in industrial and medical areas. In addition, it can be easily adapted to different devices and usage scenarios with customizable design options.

What are the differences with mechanical keypads?

The main difference between membrane keypads and mechanical keypads is their working principles and service life. While mechanical keypads contain a physical spring or switch mechanism under each key, membrane keypads have a layered structure and come into contact with the circuit on the lower layer when the keys are pressed. Therefore, while mechanical keypads require a higher pressing force, membrane keypads can work even with light touches.

Mechanical keypads are generally more durable and long-lasting, but they take up more space and require more maintenance. In contrast, membrane keypads produced by Tuşhan Elektronik stand out with their waterproof, lightweight and silent operation features. Especially in sensitive areas such as medical devices, industrial control panels and the defense industry, membrane keypads offer a more efficient solution than mechanical alternatives.

Advantages of Membrane Keypads

Membrane keypads are a preferred input unit in many sectors thanks to their compact structure and advanced material technologies. Compared to mechanical keypads, they are lighter, quieter and lower cost. In addition, they offer a user-friendly experience with their resistance to water, dust and chemicals, energy saving and ergonomic design.

Tuşhan Elektronik maximizes these advantages by using high-quality materials in the production of membrane keypads. These keypads, which have a wide range of uses from industrial devices to medical equipment, can be designed to suit every need thanks to their customizable structure. Let's examine the basic advantages offered by membrane keypads in detail below.

Durability and Long-Lasting Usage

Membrane keypads are more resistant to wear and tear because they do not contain moving mechanical components. While spring and key systems in mechanical keypads can wear out over time and cause performance loss, membrane keypads can operate smoothly for a long time thanks to flexible circuits. This structure allows the keypad to withstand hundreds of thousands of presses.

Membrane keypads produced by Tushan Elektronik are long-lasting against wear and tear thanks to high-quality materials and special production techniques. In areas requiring continuous use such as industrial machines, medical devices and automation systems, membrane keypads offer a longer-term solution than mechanical alternatives.

Water and Dust Resistant Structure

One of the biggest advantages of membrane keypads is their high resistance to water, dust and chemicals.ir. While dust and liquid can leak between the keys in mechanical keypads and cause malfunctions, membrane keypads provide protection against such external factors because they have a closed and sealed design.

Tuşhan Elektronik produces membrane keypads that are specially designed for industrial and medical devices and are resistant to water and dust. These keypads, which provide IP-rated protection, can operate without problems even in outdoor conditions and can be used for many years without requiring maintenance.

Ergonomic Design and Ease of Use

Membrane keypads offer users a comfortable use thanks to their sensitive structure that can operate with low pressure. While more force is required to press the keys in mechanical keypads, membrane keypads can be activated even with light touches. This feature reduces hand fatigue even during long-term use and offers a more comfortable experience.

Tuşhan Elektronik produces user-friendly membrane keypads by prioritizing ergonomics. Special design options, personalized key placement and different surface textures aim to increase user comfort and efficiency. Ergonomic membrane keypads provide an efficient working environment in areas that require intensive use such as hospitals, factories and laboratories.

Energy Efficiency and Low Power Consumption

Membrane keypads consume much less power than mechanical keypads. Since they work with an electrical signal, they consume less energy and extend battery life. This provides a great advantage especially in portable devices and battery-powered systems.

Tuşhan Elektronik offers environmentally friendly and economical solutions by producing membrane keypads that provide low energy consumption. In applications where power saving is critical, such as smart devices, medical equipment and automation systems, membrane keypads help reduce operating costs in the long term.

In Which Sectors Are Membrane Keypads Used?

Membrane keypads are widely used in many sectors thanks to their durable structure, resistance to water and dust, ergonomic design and low energy consumption. Their customizable structures allow them to be designed to suit different areas of use. They are frequently preferred in areas such as industrial automation, medical devices, military applications and consumer electronics.

Since these keypads have a lighter and thinner structure compared to mechanical alternatives, they can be easily used in devices with limited space. At the same time, being resistant to chemicals and harsh environmental conditions makes it a reliable input interface in demanding sectors. Below, let's examine the sectors where membrane keypads are most commonly used in detail.

Industrial Automation and Control Systems

Industrial environments include harsh conditions such as intensive use, high temperatures and dusty atmospheres. Membrane keypads can be used safely in these environments thanks to their closed and sealed structures. Machine control panels, automation systems in production lines and user interfaces of industrial equipment are the areas where these keypads are most commonly used.

Membrane keypads, which are resistant to outdoor conditions, are resistant to chemicals and humid environments. In addition, thanks to their customizable keypads, they allow operators to control the machine more efficiently and safely.

Use in Medical Devices

Environments in the healthcare sector, such as hospitals, laboratories and clinics, require special solutions in terms of hygiene and durability requirements. Membrane keypads do not harbor bacteria and viruses thanks to their smooth and cleanable surfaces. Easy disinfection makes it ideal for use in medical devices.

Requiring less maintenance than touch screens, these keypads provide a reliable control interface in sensitive medical equipment. Patient monitors, laboratory devices, dialysis machines and ultrasound devices are some of the medical devices where membrane keypads are commonly used.

Applications in Military and Defense Industries

Military and defense industry applications require resistance to extreme weather conditions, vibration, impact and electromagnetic effects. Membrane keypads exhibit excellent performance against such difficult conditions thanks to their lightweight yet robust structure.

Membrane keypads are frequently preferred, especially in military vehicles, radar systems, communication equipment and portable devices designed for field operations. The advantage of working with low noise in secret missions is an important feature that makes it more attractive in the defense industry.

Usage in Electronic Devices and Home Appliances

Consumer electronics and home appliances are one of the most common areas where membrane keypads are used. Offering a more aesthetic and compact design provides advantages for home users. Especially remote controls, microwave ovens, coffee machines and digital scales are among the devices that benefit from this technology.

In addition to these, computer accessories, security systems, POS devices and smart home systems are also equipped with membrane keypads. Silent operation, long life and low power consumption are the biggest factors in electronic device manufacturers' preference for this technology.

What to Consider When Choosing a Membrane Keypad?

Membrane keypads are input interfaces that can be produced with different features depending on the purpose of use and environmental factors. Factors such as durability, ergonomics, resistance to water and chemicals are the basic criteria to consider when choosing the right keypad. Models manufactured specifically for industrial, medical or military use may have different features than standard consumer electronics products.

- Material Quality and Production Standards: The durability of membrane keypads is directly dependent on the quality of the materials used and the production process. Models manufactured from high-quality polycarbonate or polyester materials are more resistant to abrasion and offer long-term use. In addition, key feel, pressure resistance and the life of circuit components are directly related to the quality standards applied in the production process.

Membrane keypads that are resistant to scratches, impacts and heat should be preferred, especially in industrial or medical devices that are used intensively. The manufacturer's compliance with ISO 9001, RoHS or other industry standards indicates that the product is sufficient in terms of quality and reliability. - Suitable for the Working Environment: Membrane keypads can be designed to be used in different environmental conditions. Humid, dusty, hot or chemically exposed environments require certain technical requirements to be met. Models with water and dust resistance certificates such as IP65 and IP67 are more suitable for harsh working conditions.

- Customizable Design Options: Membrane keypads can be customized to suit different sector and device requirements. Features such as key placement, backlighting, embossed keys, different graphic designs and brand logos can be shaped according to the area of use. Special icons and colored key groups, especially for industrial control panels or medical devices, can increase the user experience. In addition, more effective use can be provided with audible or tactile mechanisms that provide feedback.

- Long-Term Cost and Maintenance Advantages: Membrane keypads provide a cost advantage in the long term, as they have lower maintenance requirements and a longer life compared to mechanical alternatives. Having fewer moving parts prevents mechanical failures and makes them more resistant to user errors. Especially in industrial or medical applications that require continuous use, the minimum need for regular maintenance offers businesses time and cost savings. A membrane keypad made of quality materials can perform flawlessly for years when used properly.

Membrane Keypad Manufacturing Process and Technologies

Membrane keypad manufacturing is a technical process consisting of many stages, from material selection to circuit design, from printing techniques to quality control processes. Depending on the area of use, different materials and production methods that increase durability are preferred. Meeting quality standards at every stage of the production process ensures consistent performance and long-lasting use.

- Material Selection and Layer Structure: Membrane keypads generally have a multi-layer structure. The upper layer contains the graphic interface, the middle layer contains circuit components, and the lower layer contains protective support. The materials used include flexible polyester, polycarbonate, and conductive ink-coated circuits. Each of these layers is designed to be resistant to mechanical wear, moisture, and chemical effects. In addition, customization options for backlighting and different key pressure levels can be included in the production process.

- Printing Techniques and Circuit Design: Key symbols and graphic details are created using screen printing, digital printing or laser engraving techniques on membrane keypads. The conductive circuit design is created by printing with carbon or silver-based ink, and these circuits provide the detection of the keys. The circuit design includes sensitivity, feedback time and pressure pairk values are optimized. Circuits specially designed for different areas of use are subjected to tests that increase mechanical and electrical durability.

- Quality Control Process and Test Stages: In the final stage of the production process, membrane keypads are subjected to various durability and performance tests. These include:

- Pressure and key response time tests

- Water and dust resistance tests

- Chemical resistance tests

- Electrical conductivity and connection checks